|

|

Post by heem6 on Apr 17, 2010 21:20:58 GMT -5

Hey, that's pretty cool, Bo!

|

|

|

|

Post by Bodaggit23 on Apr 18, 2010 2:00:26 GMT -5

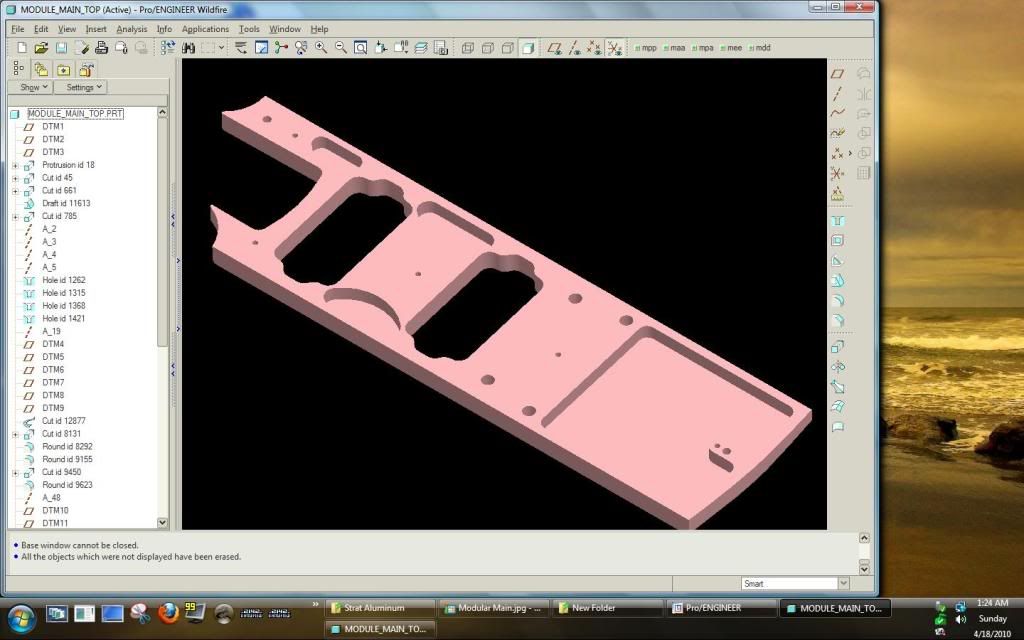

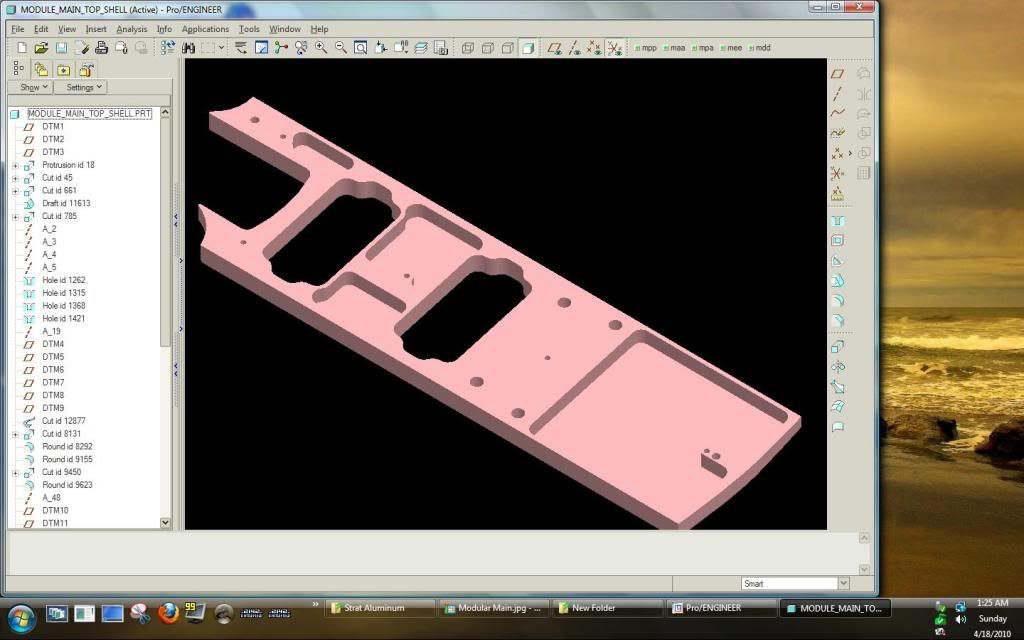

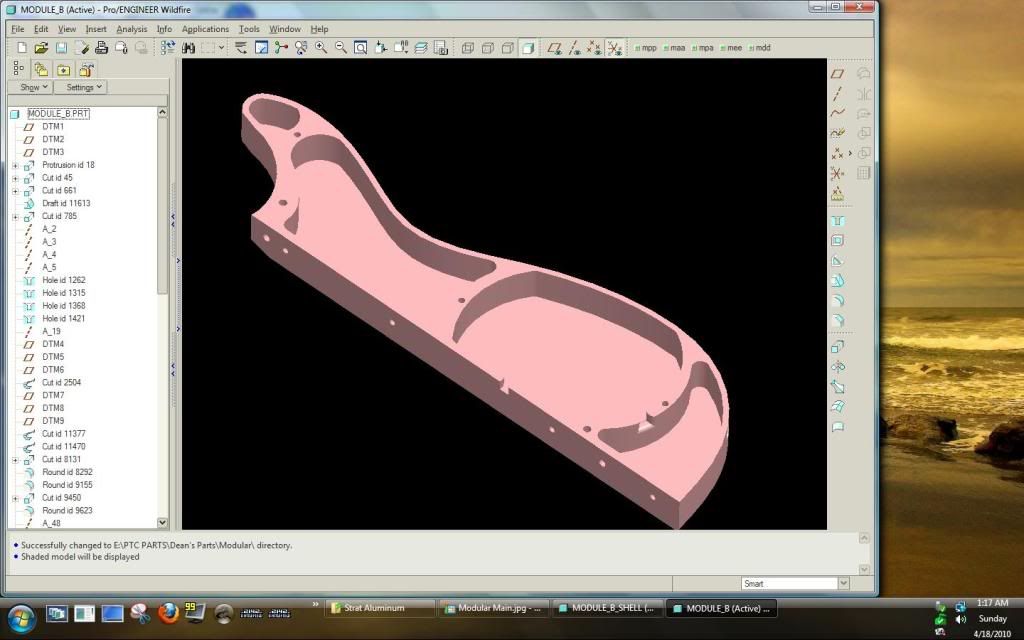

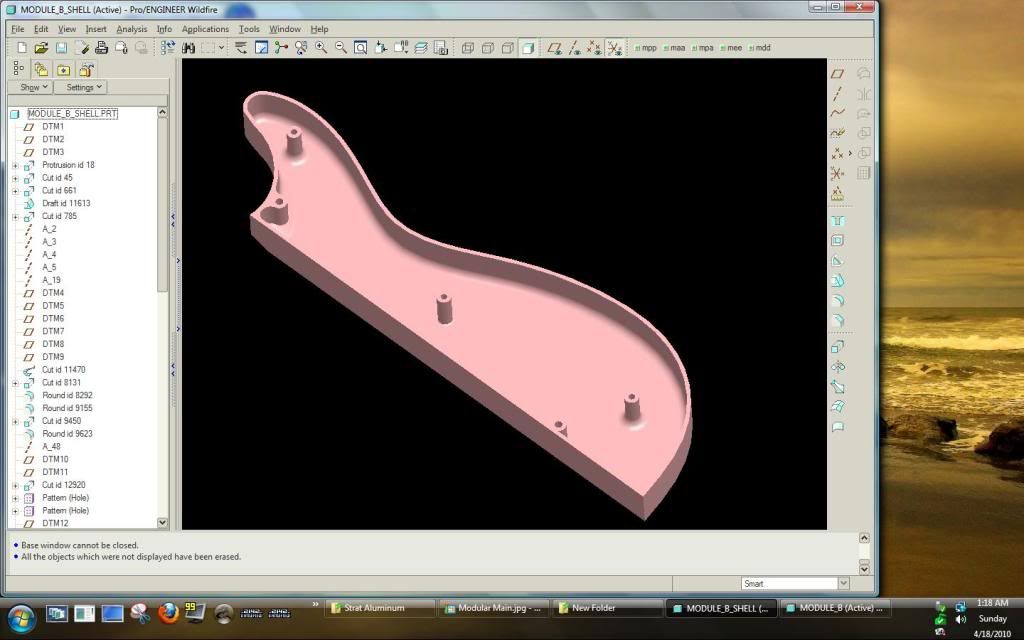

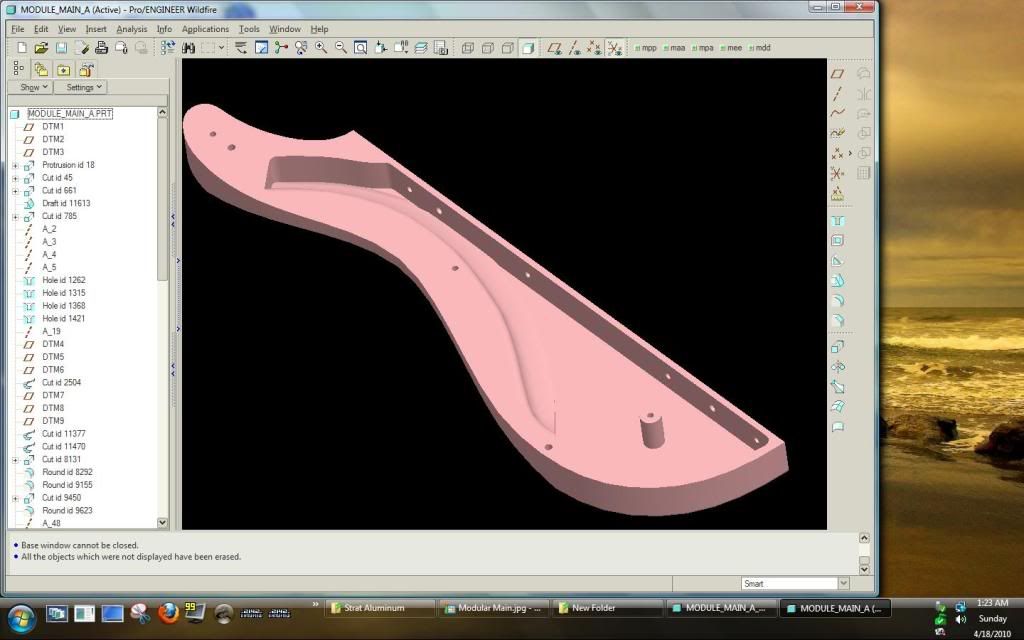

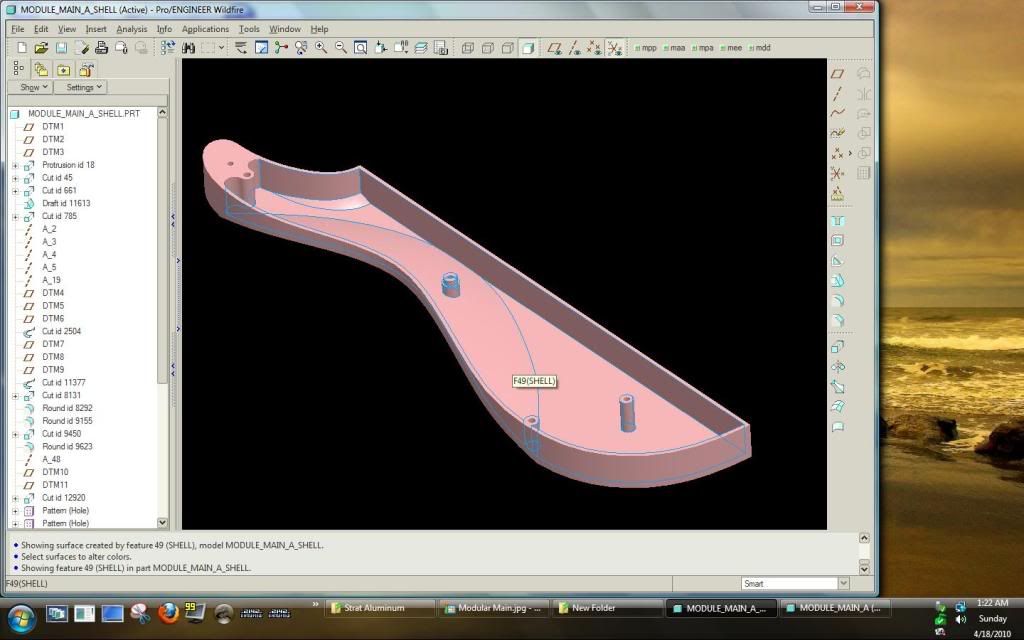

UPDATE:

Ok, so I tweaked 4 pieces of the body to reduce more weight.

I reduced the shell thickness of these 4 parts from .15" to .1" in addition to removing unnecessary ribbing.

Basically, anywhere I machined it to reduce weight, it was .15" before, and now it's .1"

I also refined the cut to the upper bottom module to match the outside contour.

That was tricky, and this is the way I wanted it to begin with, but I couldn't figure out how to do it, but I got it.

The assembled body by itself now weighs 7.3 pounds...

That should bring the finish weight to around 8-9 pounds.

The assembled body weighed 9.8 pounds tonight, before I started machining!

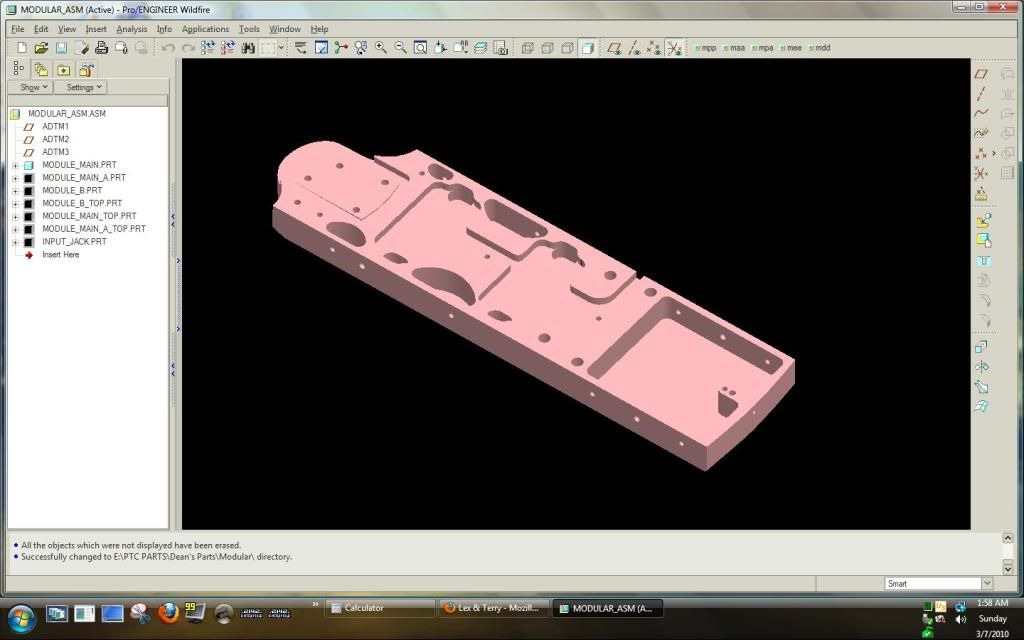

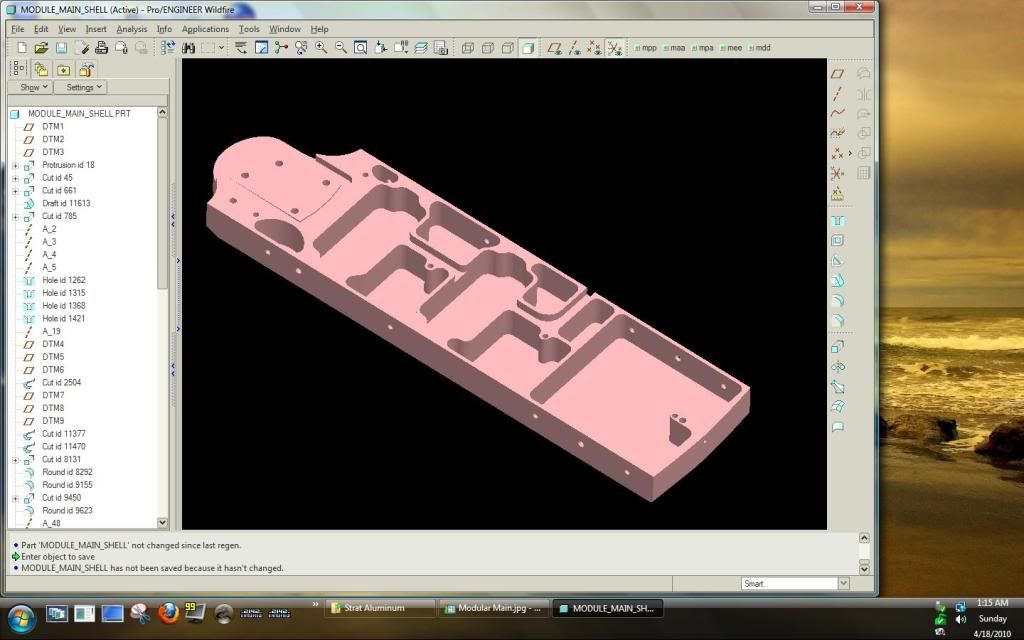

Here's some detailed pics of the changes.

Main Top Module, original and now (not much changed) :  Main Module, original, and now (significant weight reduced): Main Module, original, and now (significant weight reduced):  Lower Bottom Module, original and now (substantial weight reduced): Lower Bottom Module, original and now (substantial weight reduced):  Upper Bottom Module, original and now (major weight reduced): Upper Bottom Module, original and now (major weight reduced):

Some assembly pics:

|

|

|

|

Post by nickwellings on Apr 18, 2010 11:02:50 GMT -5

Those pics make me drool.

|

|

mrfist9

Full Member

Ya I'm just that Awesome

Ya I'm just that Awesome

Posts: 191

|

Post by mrfist9 on Apr 18, 2010 12:13:31 GMT -5

I want one how much?

|

|

|

|

Post by Bodaggit23 on Apr 18, 2010 13:34:13 GMT -5

|

|

|

|

Post by lbeast on Apr 18, 2010 14:25:03 GMT -5

Bo, when you get that design down to one solid piece with a tremolo, I'll be the first in line to buy one.

...and, oh yeah, your tremolo locking thingy.

|

|

|

|

Post by nickwellings on Apr 18, 2010 14:33:49 GMT -5

What would you seriously estimate retail to be at, Bod? Or how much $$$ has it run to so far? Are you allowed to say?

|

|

|

|

Post by Bodaggit23 on Apr 18, 2010 17:49:12 GMT -5

Beast, you're just not gonna let me alone until I make a full HM are you?  I just might, but it will be two piece, not one. I just might, but it will be two piece, not one.

One solid piece would be easy, but you'd have to pocket the whole rear of the guitar to be able to play it!

Nick, It greatly depends on what my time is worth.

This particular material only cost me about $60, and the

$265 guitar I used as a donor for the neck and hardware.

So out of pocket, I only have $325 into it.

Now for my big BUT:

It has taken,

about 30 hours of design time,

about 10 hours to program the parts, and

about 20 hours total machine time, and

about 5 hours to polish it.

If I charged $20/hour, this guitar would have cost $1625 to make, from scratch.

How much do you guys think it's worth?

|

|

mrfist9

Full Member

Ya I'm just that Awesome

Ya I'm just that Awesome

Posts: 191

|

Post by mrfist9 on Apr 18, 2010 20:24:08 GMT -5

I personally believe you should just sell the bodies. How much did all the Aluminum cost? If you make a design that works and get the program to the exact details. It would be all machine. For example if you completely remade one exactly how it is now. Wouldn't it just be machine and polishing time? Correct me if I am wrong.

|

|

|

|

Post by Bodaggit23 on Apr 18, 2010 20:53:23 GMT -5

How much did all the Aluminum cost? Wouldn't it just be machine and polishing time?

Yes, of course, the next one would be just machine and polish time.

I could make 10 of these exact same bodies if I wanted to, or more with the programs I already have.

Even with just machine and polish time, you're still looking at a $400-500 body.  |

|

|

|

Post by nickwellings on Apr 19, 2010 1:05:59 GMT -5

Say it had very unique features, and sounds unique, which it does, you could probably retail them for about 1.2k maybe?? I am not a marketing person though!

|

|

|

|

Post by Bodaggit23 on Apr 20, 2010 2:01:45 GMT -5

6.8 pounds!

I remachined the last two pieces tonight, and the body weighs 6.8 pounds!

I think I should shoot for 6 even...Muahahaha!

I took video of me machining the last part tonight.

It's uploading to Youtube right now, and I'll post it tomorrow. ;D

|

|

|

|

Post by Bodaggit23 on Apr 20, 2010 7:20:20 GMT -5

|

|

|

|

Post by heem6 on Apr 20, 2010 15:19:02 GMT -5

Wow. Interesting to see how all that is done! What kind of tape are you using that would hold the body down while the robot thing is machining it? Hard to believe that tape would hold that well. Although I guess they use tape to partially hold on airplane wings, don't they?

So this is supposed to lower the resonant frequency of the guitar's tone as well?

Done Deal!

|

|

|

|

Post by lbeast on Apr 20, 2010 19:38:04 GMT -5

Beast, you're just not gonna let me alone until I make a full HM are you?  I just might, but it will be two piece, not one. I just might, but it will be two piece, not one.

One solid piece would be easy, but you'd have to pocket the whole rear of the guitar to be able to play it!

I would gladly pay $4-500.00 for an aluminum HM body I could put one of my spare Steelers on. What a unique piece it would be. You'd see it on Antique's Roadshow in 2050. "Now this piece was made by a self taught luthier by the name of Bo Daggit of the North Dakota Daggits". Magic Pixie dust sound here. Price range=4.2 Billion Dollars.

The video you made of the 3 axis machining process was Oscar Award winning in my book. Bravo. Bravo. Encore. Encore. |

|

/>

/>

/>

/>